Testing Center

Testing Center

Quality assurance is based on the perfect quality management system.

Zhanmei has gathered a number of professional elites who are engaged in product quality inspection and research and development. Our commitment is based on the product quality, with the business philosophy of "excellence and superior quality", to continuously improve the product quality and service, and lead Zhanmei to continuously grow and develop.

Zhanmei has the physical and chemical testing equipment valued more than 2 million Yuan, three Germany-imported spectral analyzers, sclerometer, tensile tester and chemical laboratories, as well as professional and experienced quality engineering and technical personnel, and rigorous work and professionalism, which provide the reliable quality assurance for the products of Zhanmei.

-

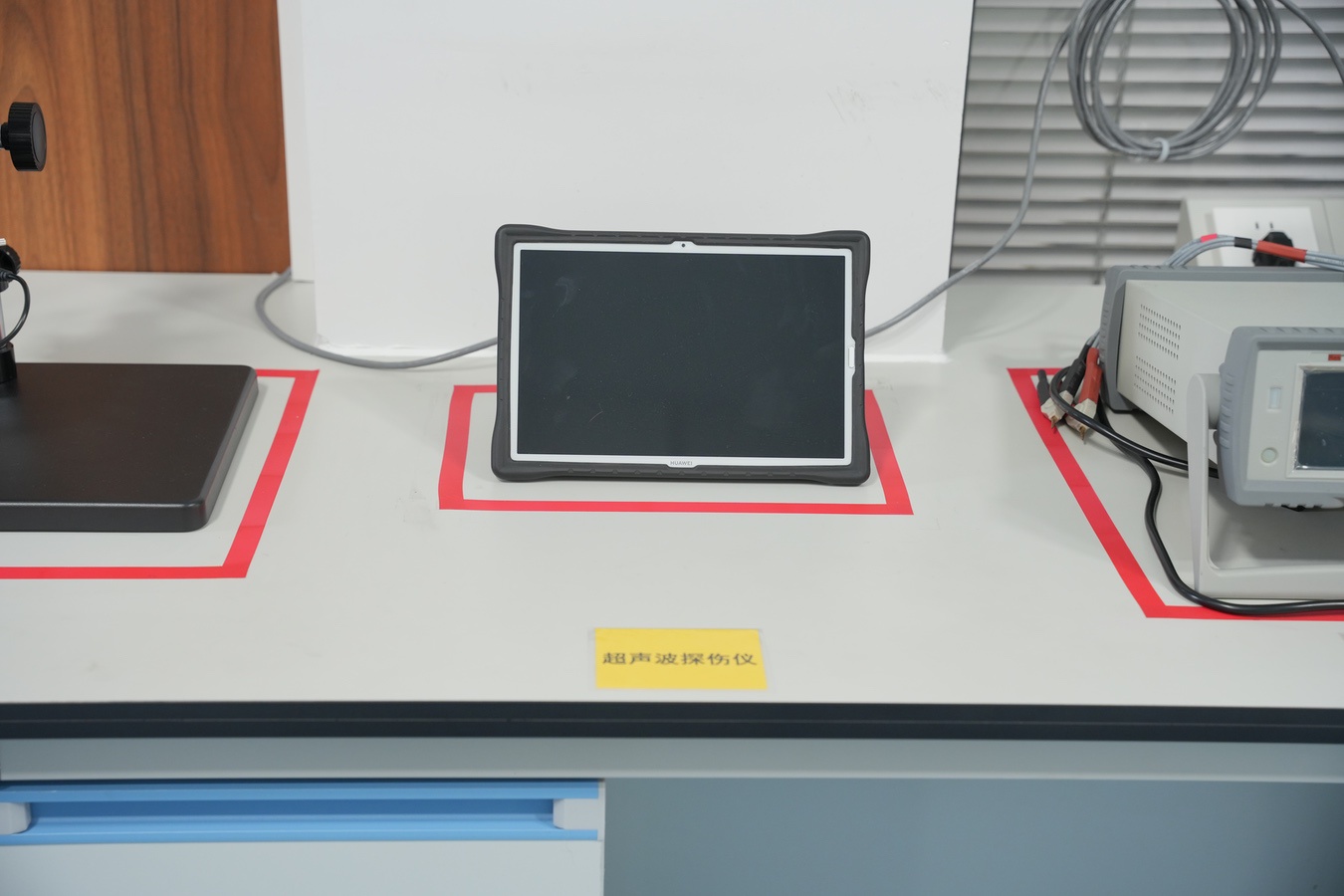

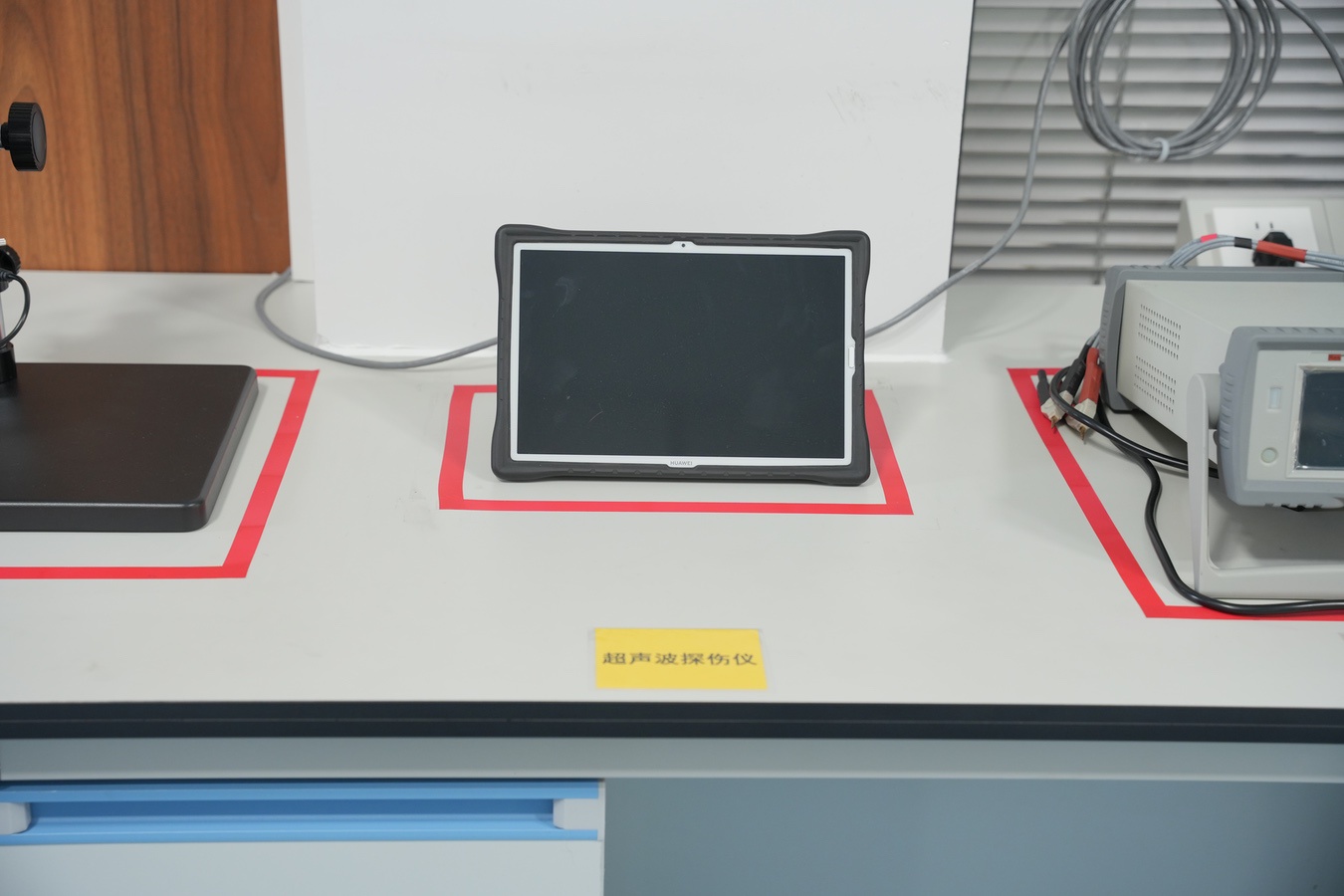

Ultrasonic flaw detector

Ultrasonic flaw detector

-

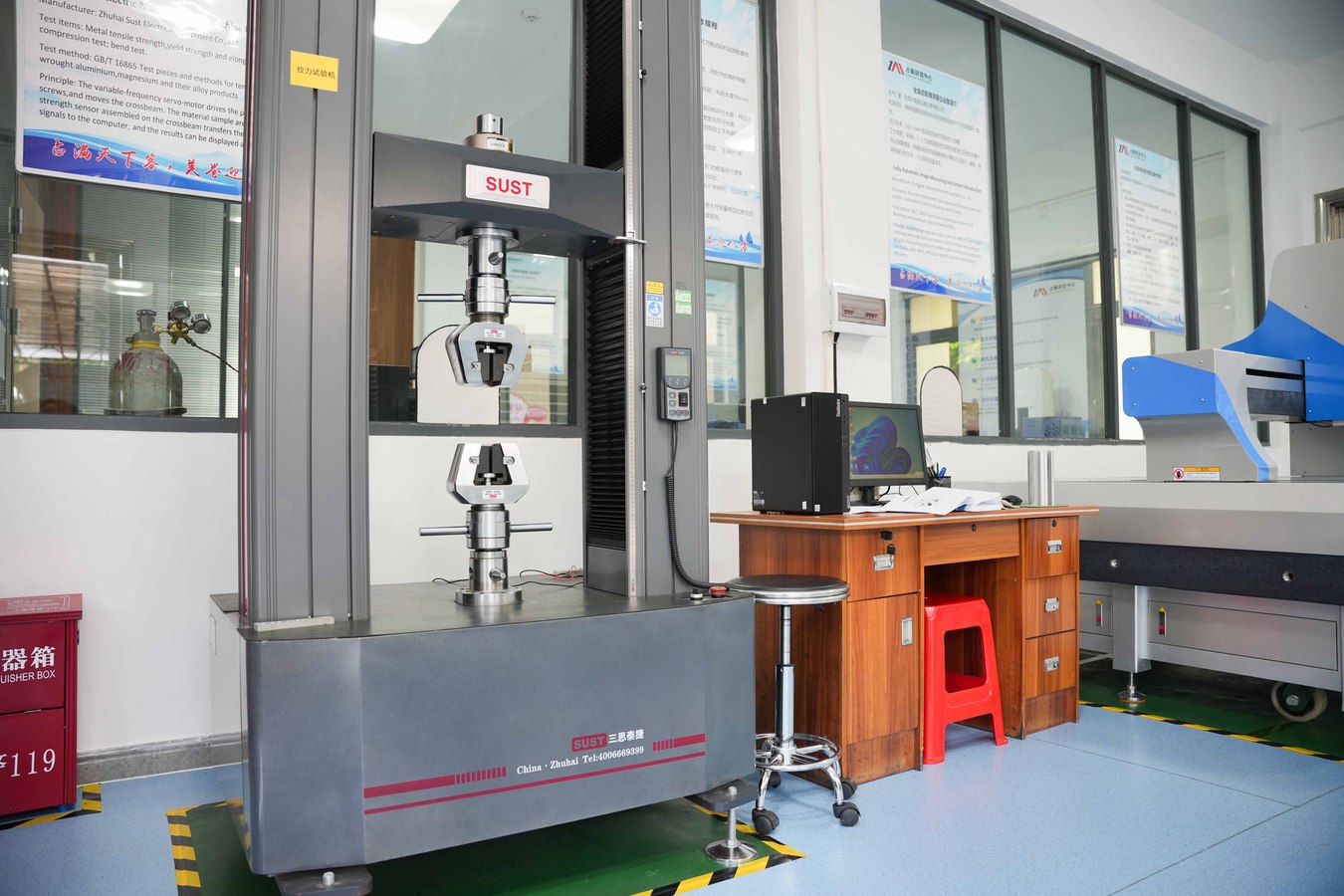

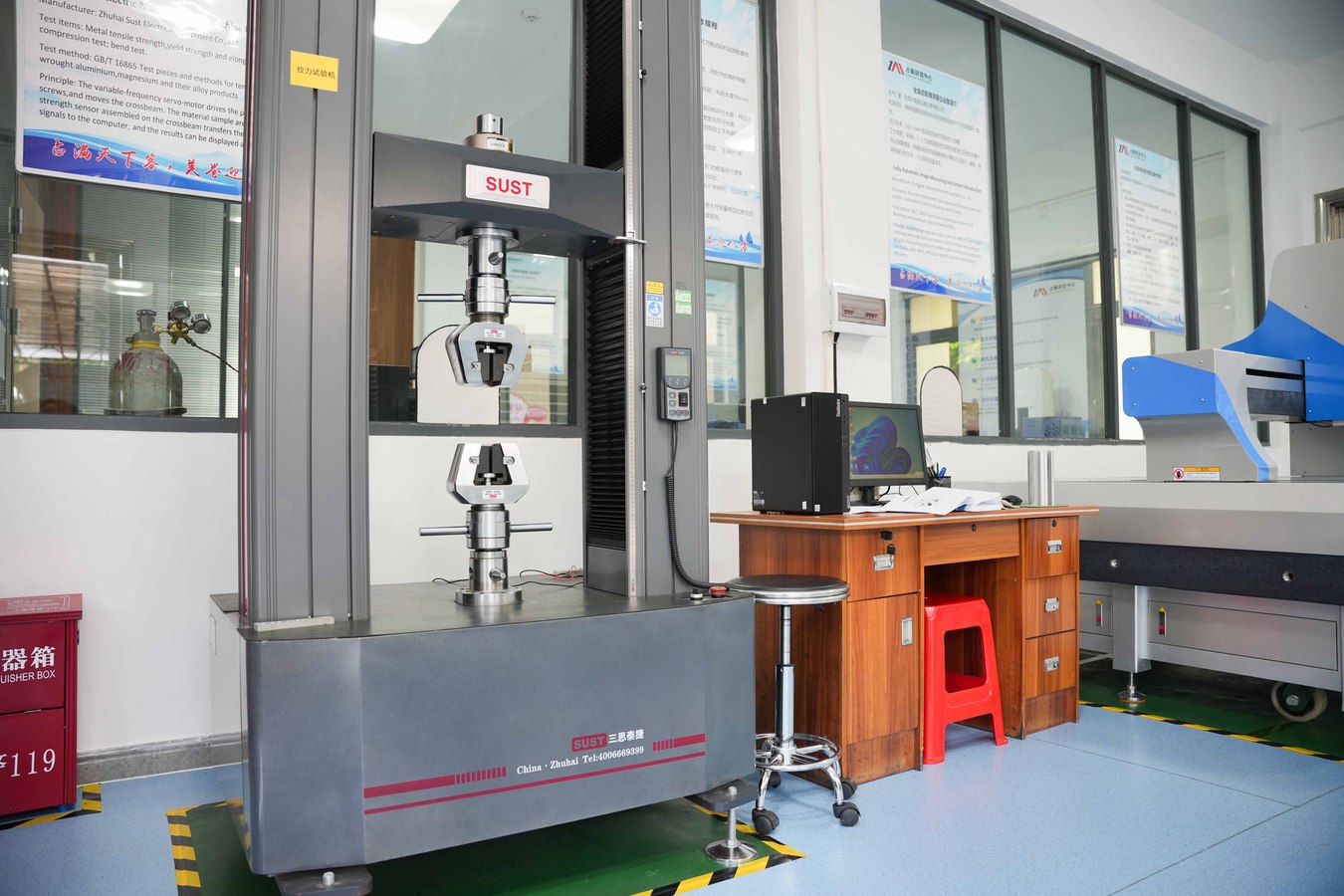

Electronic universal testing machine

Electronic universal testing machine

-

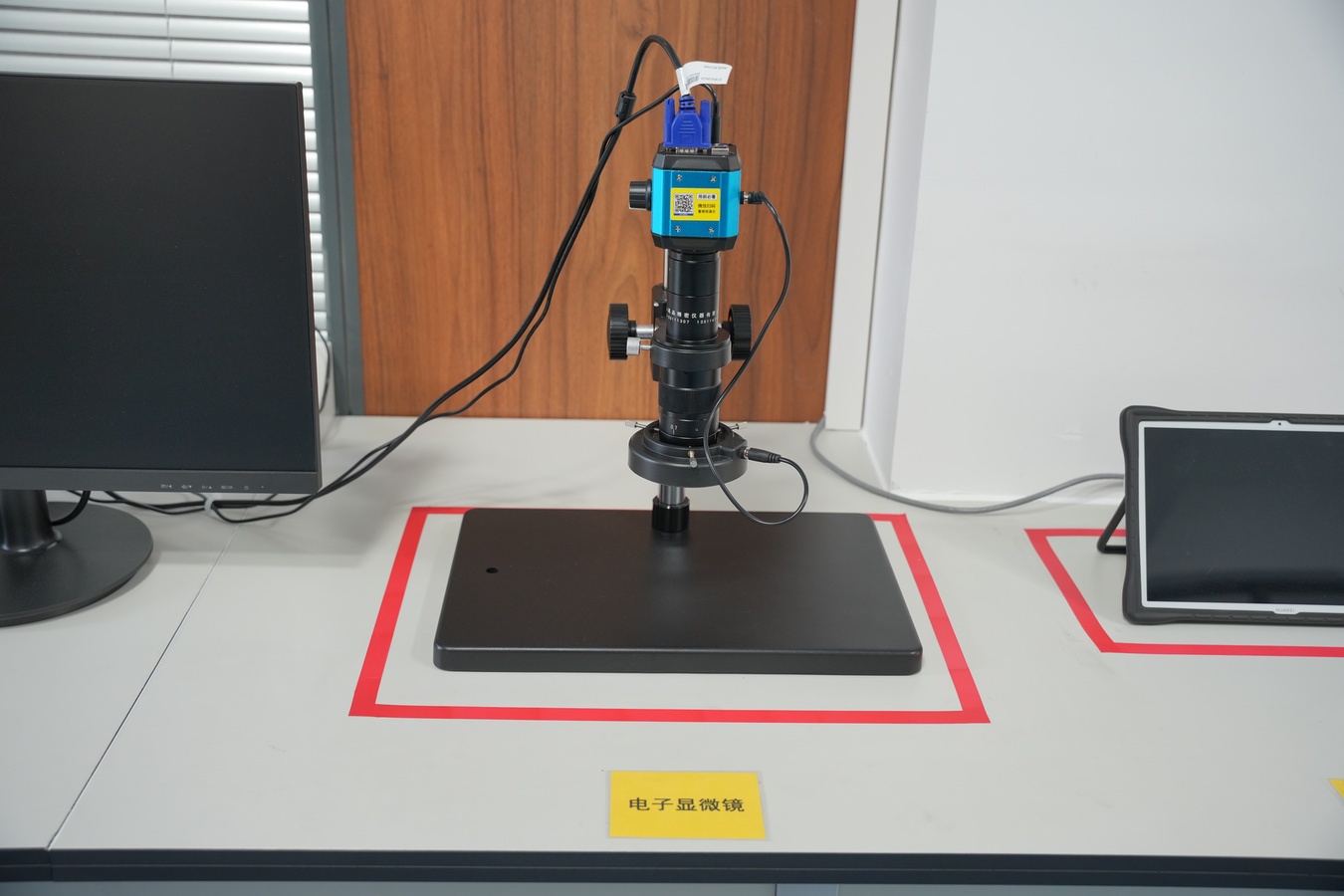

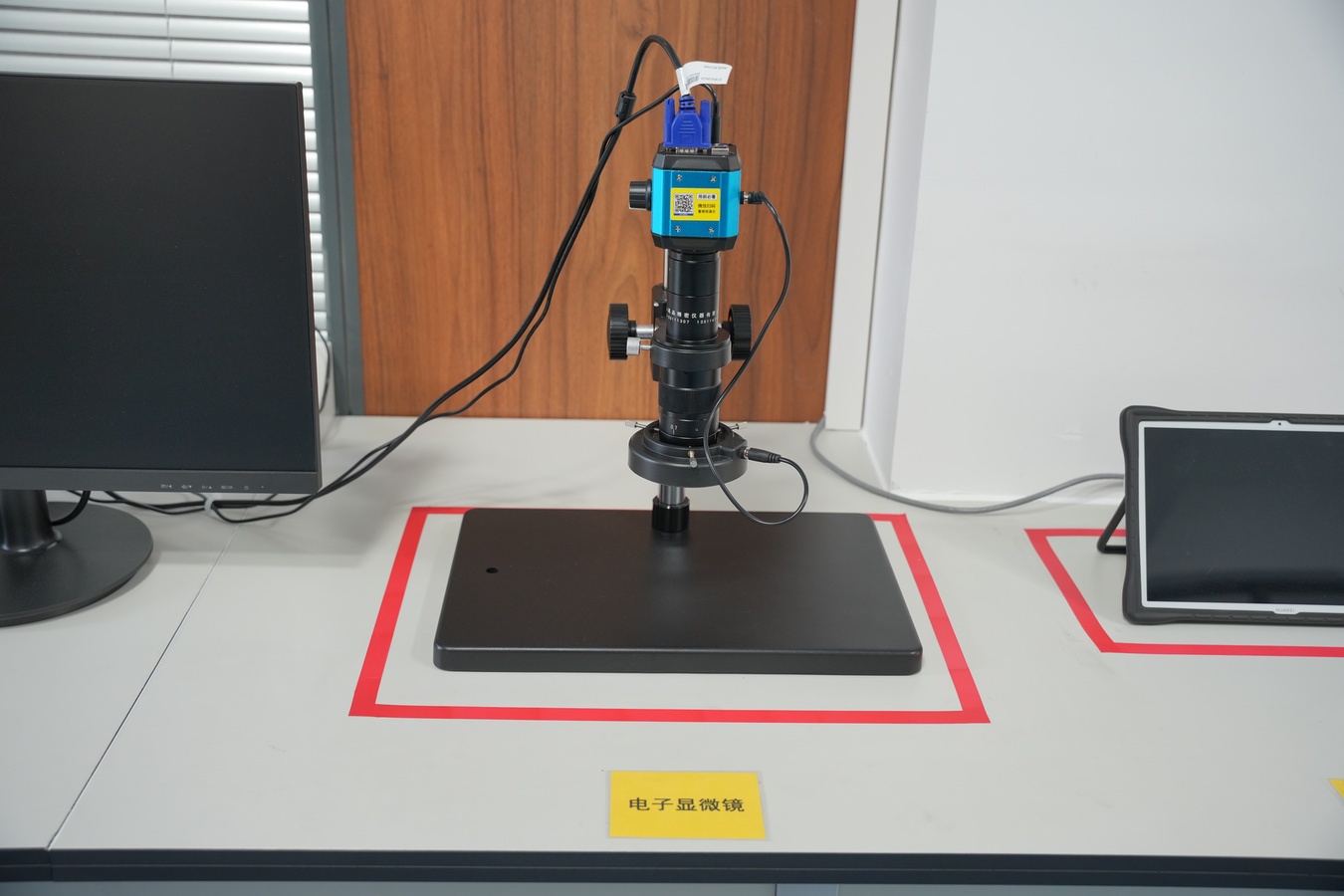

Electron microscope

Electron microscope

-

2D scanner

2D scanner

-

Metallurgical polisher

Metallurgical polisher

-

Metallurgical microscope

Metallurgical microscope

-

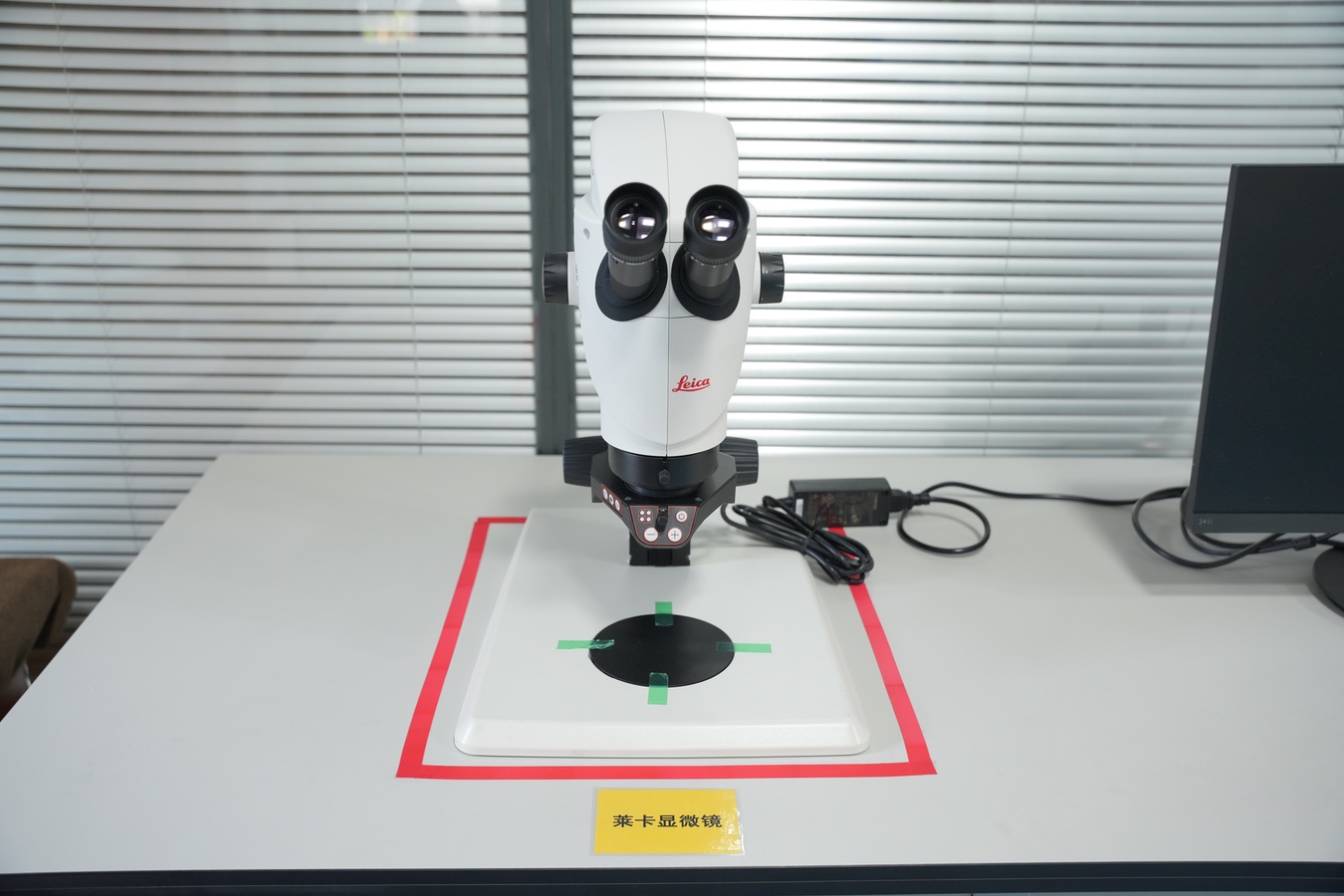

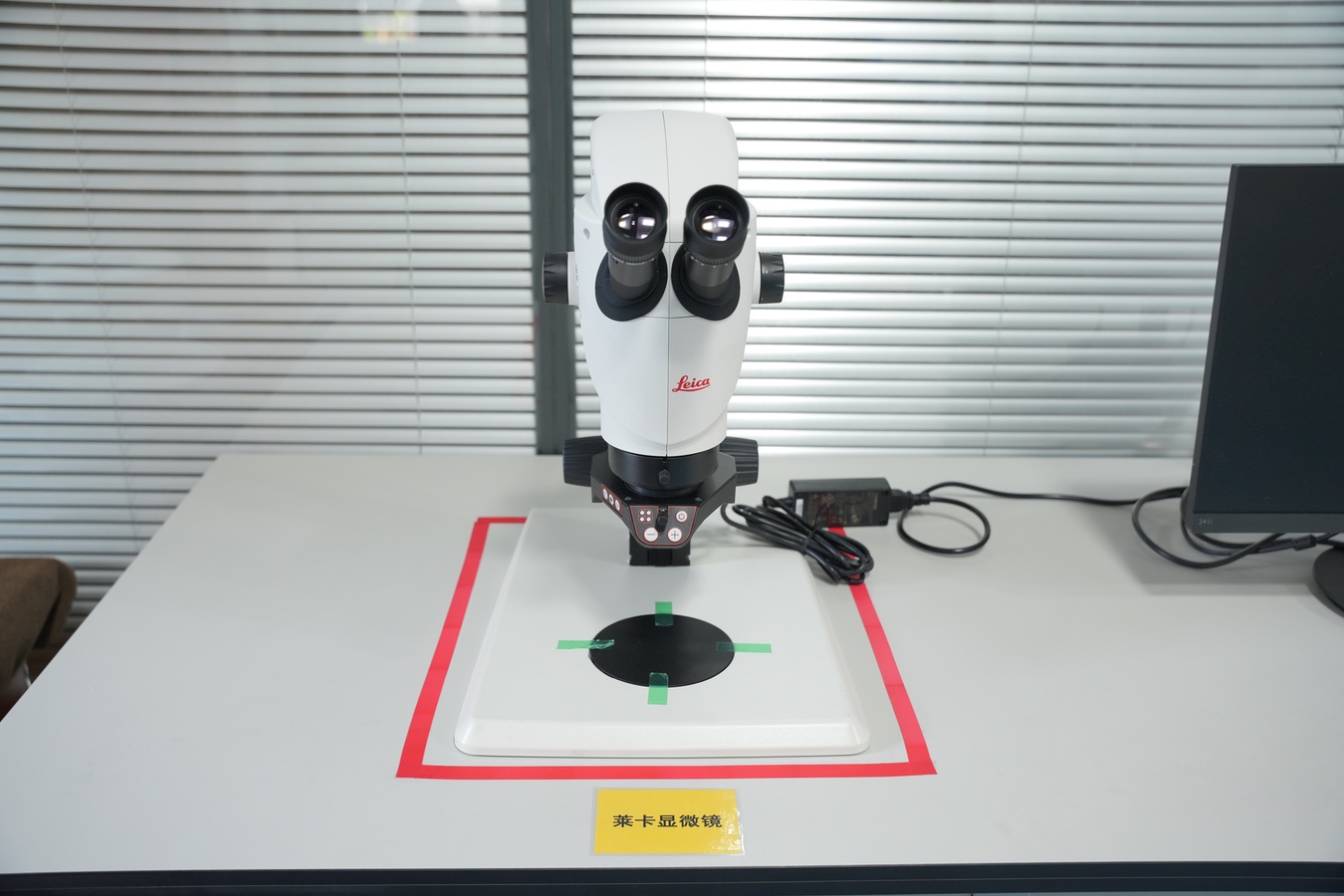

Leica microscope

Leica microscope

-

Laboratory

Laboratory

-

Laboratory

Laboratory

-

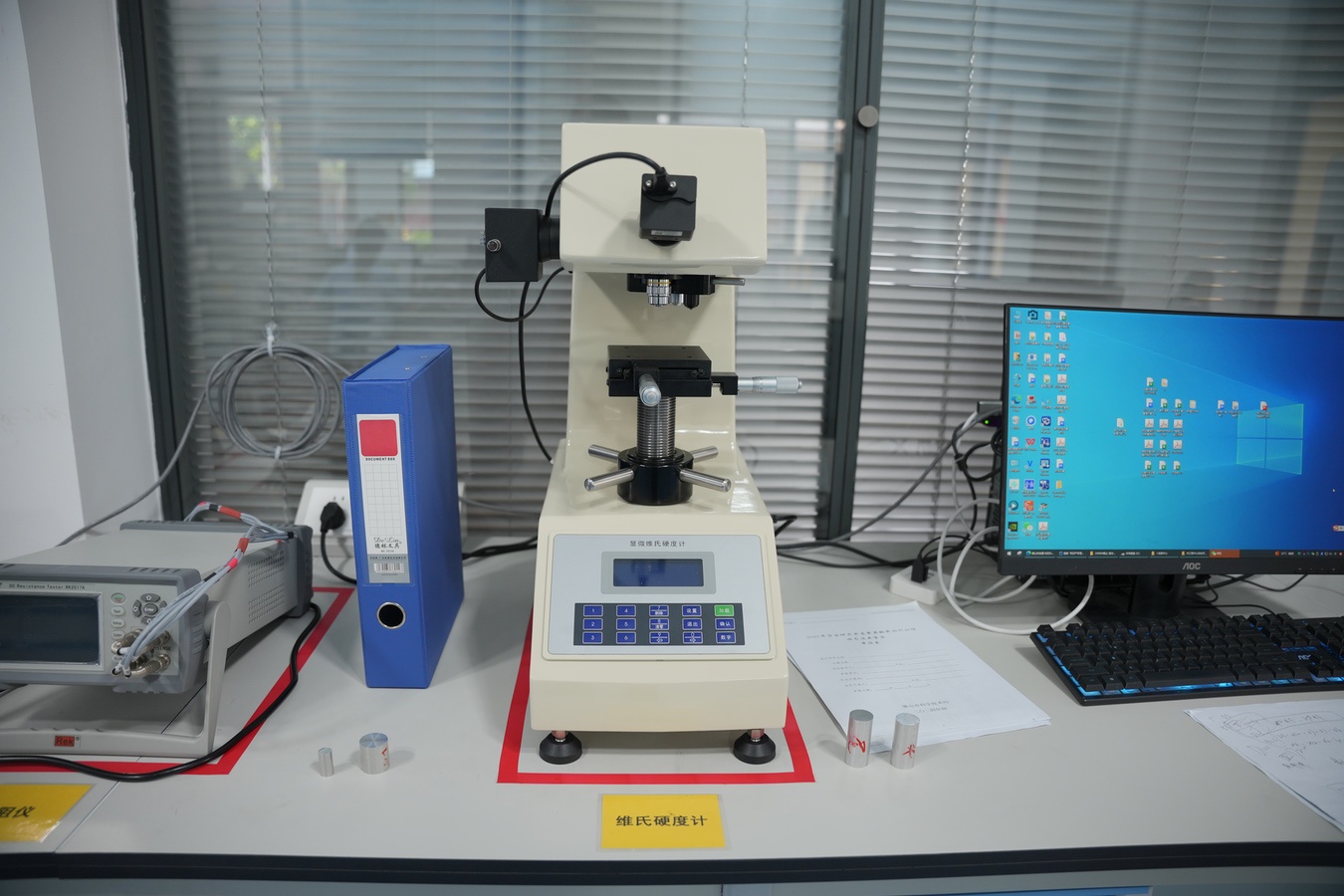

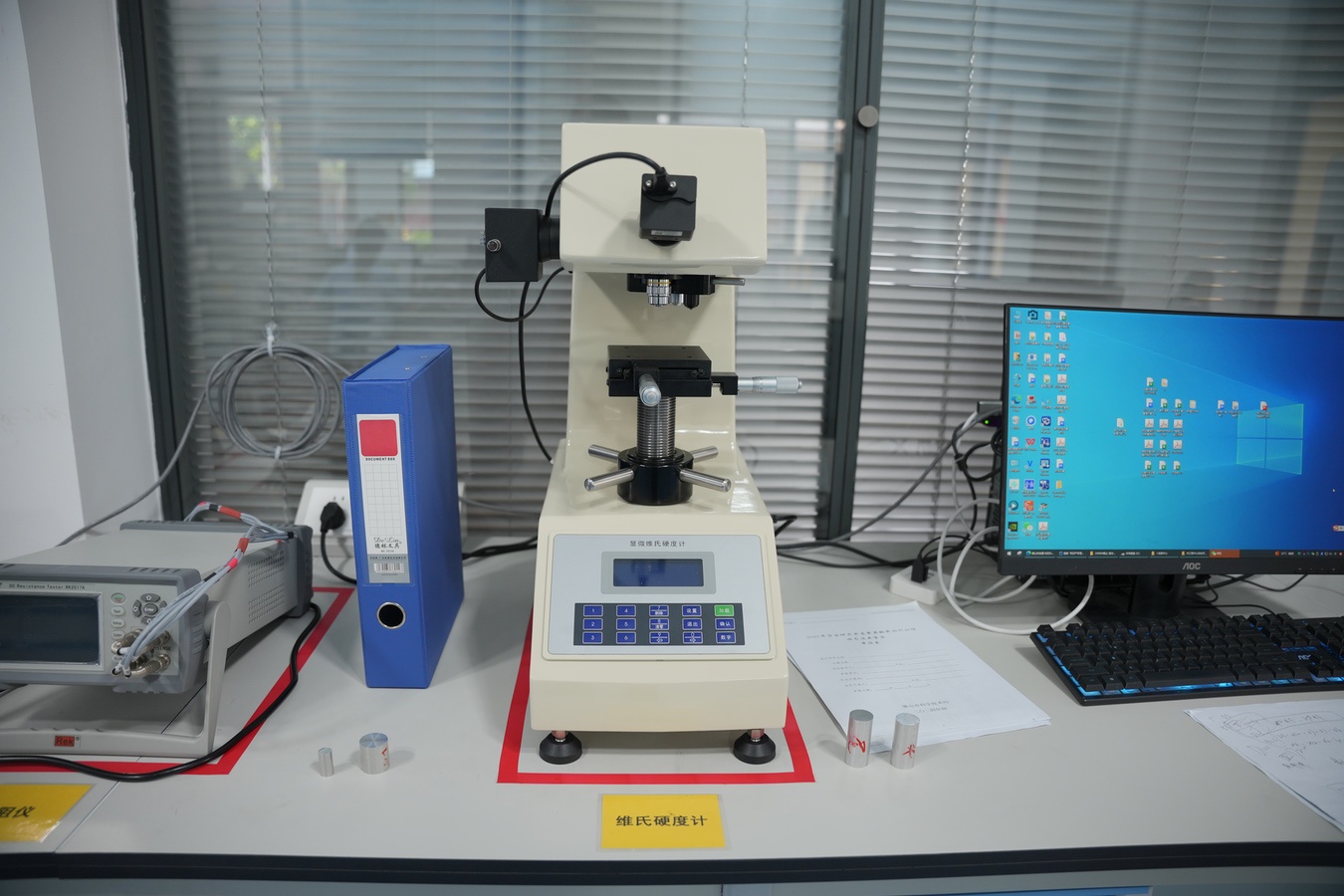

Vickers Hardness Tester

Vickers Hardness Tester

-

Jianmei R&D Center

Jianmei R&D Center

-

Direct reading spectrometer

Direct reading spectrometer

| Shape |

Basic size |

Diameter tolerance |

Tolerance of roundness (not greater than) |

Bending degree (no greater than) (mm) |

Length deviation(mm) |

| polishing |

Drawing |

Extrusion |

polishing |

Drawing |

Extrusion |

| Round bar |

≥2-8 |

0-0.018 |

0-0.035 |

— |

0.0025 |

0.005 |

— |

1 |

±10 |

| >8-15 |

0-0.025 |

0-0.04 |

0-0.15 |

0.003 |

0.007 |

— |

1 |

±10 |

| >15-25 |

— |

0-0.07 |

0-0.18 |

— |

0.010 |

— |

1.5 |

±10 |

| >25-36 |

— |

0-0.12 |

0-0.21 |

— |

0.015 |

— |

1.5 |

±10 |

| hexagonal and special-shaped bars |

≥4-8 |

— |

0-0.03 |

0-0.15 |

— |

0.005 |

— |

1.5 |

±10 |

| >8-13 |

— |

0-0.04 |

0-0.18 |

— |

0.007 |

— |

1.5 |

±10 |

| >13-21 |

— |

0-0.07 |

0-0.18 |

— |

0.010 |

— |

3 |

±10 |

| >21-26 |

— |

0-0.12 |

0-0.21 |

— |

0.015 |

— |

3 |

±10 |

|

Note: The enterprise standard of Zhanmei is in line with GB4425-84 standard, and its polishing and drawing accuracy can fully meet the processing needs of high-end imported CNC machines and automatic lathes, to develop the delivery tolerances and grade accuracy according to the actual needs of customers.

| variety |

Specifications |

Japan |

Main characteristics and Applications |

| name |

grade |

state |

grade |

Code |

| free cutting lead brass |

Hpb59-2 |

drawing

polishing |

Φ2-35

S4-36

Φ3-35 |

C3604 |

C3604BDS |

The superior cutting performance is available for bolts, nuts, small screws, shafts, gears, valves and components for watches, carburetors, IT industry and precision instruments. The GD high-precision hexagonal brass rod can be used for the imported high-precision CNC machine tools to process and produce the high-precision components. |

| cold riveting lead brass |

Hpb63-3 |

drawing

polishing |

Φ3-35

S4-36

Φ3-35 |

C3560 |

C3560BDS |

The superior cutting performance with excellent extension is available for the components that are subject to both cutting processing and cold riveting processing, and is mainly used for electrical switching components and enrichment valve piston of carburetor. |

| forged lead brass |

Hpb59-1 |

drawing

extrusion |

Φ

S5-36

Φ

S8-36 |

3771 |

C3771BD

C3771BE |

The excellent hot forging performance and processing performance are available for air-conditioning valve, valve core, automotive valve and other complex high-precision parts, as well as high-grade plumbing equipment, case, strap, luxury hardware jewelry, locks, handles and so on. |

|